Jewelry has always been a fusion of art and craftsmanship. Traditionally, skilled artisans shaped metals, set stones, and polished surfaces by hand, combining creativity with painstaking precision. Today, technology is transforming the jewelry industry, creating new possibilities in design, production, and quality control—without compromising the artistry that defines fine jewelry.

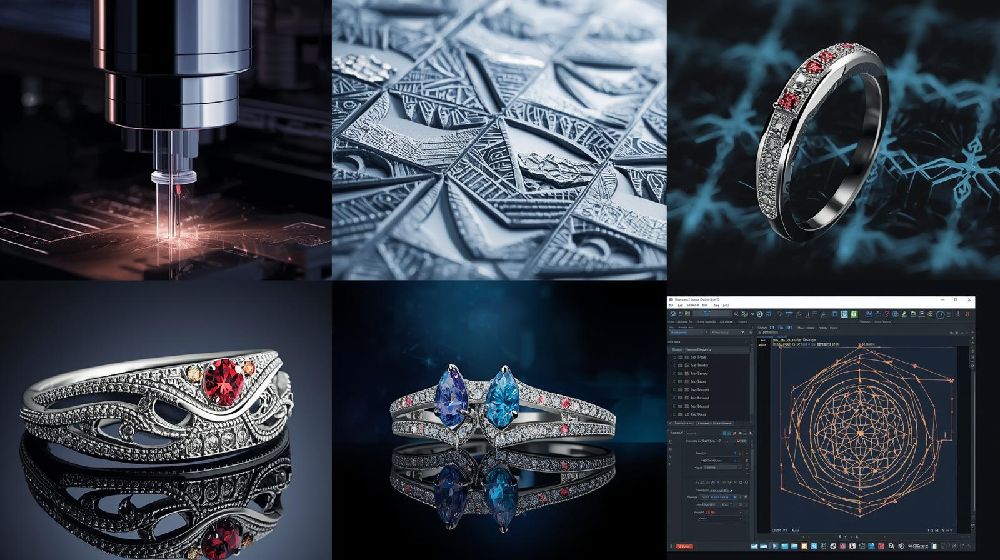

Digital Design: From Sketch to Screen

The first major shift in jewelry design is the use of Computer-Aided Design (CAD). CAD allows designers to create intricate 3D models on a computer before a piece is ever physically crafted. With CAD:

Designs can be visualized from all angles

Modifications can be made instantly

Complex patterns, textures, and structures become achievable

This digital precision reduces material waste and accelerates the journey from concept to prototype.

CNC and Laser Technology: Precision Meets Craftsmanship

Once designs are digitized, CNC (Computer Numerical Control) machines and laser technology bring them to life with incredible accuracy. These tools allow:

Micron-level precision in cutting and shaping metals

Seamless joints through laser welding

Intricate details that were previously impossible to achieve by hand

Advanced machinery ensures that each piece maintains both structural integrity and visual perfection.

3D Printing: Rapid Prototyping and Innovation

3D printing has revolutionized jewelry prototyping. Designers can quickly print wax or resin models to:

Test fit and comfort

Refine design elements

Showcase prototypes to clients before production

This speed and flexibility encourage experimentation and creativity without the high cost of traditional trial-and-error methods.

Smart Materials and Innovative Alloys

Technology has also enabled the development of new alloys and composite materials that improve durability, reduce weight, and maintain shine. From gold alloys engineered for strength to sustainable metals for eco-conscious consumers, material science is now an integral part of jewelry innovation.

Quality Control in the Digital Age

Digital tools and sensors allow manufacturers to monitor every step of production. Jewelry can now undergo:

Automated measurements for thickness and weight

Surface analysis to ensure flawless finishes

Structural integrity checks

The result is consistent high-quality jewelry, even in large-scale production.

Sustainability Through Precision

Technology also supports sustainability in jewelry manufacturing. By reducing waste, optimizing material usage, and improving production efficiency, brands can create luxury pieces that are environmentally responsible.

Bridging Art and Technology

While machines and software enhance precision, the human touch remains essential. Skilled artisans continue to polish, set stones, and apply finishing touches, blending creativity with digital perfection. Technology does not replace craftsmanship—it elevates it, making designs more intricate, durable, and innovative.

The Future of Jewelry Manufacturing

As technology continues to evolve, we can expect:

Lighter and stronger designs

Greater customization and personalization

Smarter, data-driven production processes

Integration of AI and digital marketing to anticipate consumer trends

The combination of tradition and innovation ensures jewelry remains both timeless and forward-looking.

Final Thoughts

Technology is transforming jewelry from a purely handcrafted art into a precision-driven craft that retains beauty while embracing efficiency and innovation. By leveraging CAD, CNC, laser welding, 3D printing, and advanced materials, the industry is pushing the boundaries of design, production, and sustainability.

In the modern era, jewelry is not just worn—it is engineered, designed, and crafted with technological mastery.